Quality control has long represented both a critical safeguard and a persistent bottleneck in manufacturing. For decades, it has relied on the sharp eyes and experience of human inspectors—a system with inherent and unavoidable limitations. Today, we stand at an inflection point. Artificial Intelligence, powered by machine learning and advanced computer vision, is not merely augmenting this process but fundamentally re-engineering it.

The result? Defect detection rates that consistently surpass human capabilities, unprecedented consistency, and a dramatic reduction in operational costs. This isn't just an incremental improvement; it's a paradigm shift for quality assurance.

The Inevitable Limitations of Human-Led Inspection

To understand the revolution, we must first acknowledge the constraints of the traditional model. Human inspectors bring invaluable experience and cognitive judgment, but they operate within biological and psychological limits:

- The Fatigue Factor: Attention and accuracy inevitably decline over long shifts, especially during repetitive visual tasks. A missed defect at hour seven of a shift is often a matter of human biology, not incompetence.

- Inconsistent Standards: What one inspector classifies as a minor cosmetic flaw, another might deem a critical defect. This subjectivity leads to variability in product quality and compliance risk.

- Physical and Speed Limitations: The human eye cannot process images at the speed of a modern production line, nor can it reliably detect micrometer-level anomalies or subsurface flaws.

- The High Cost of Expertise: Training and retaining skilled quality control personnel is expensive, and their expertise doesn't easily scale across multiple production lines or global facilities.

These limitations create a costly equation: higher scrap rates, the risk of "escapes" (defects that reach the customer), and continuous tension between throughput and quality.

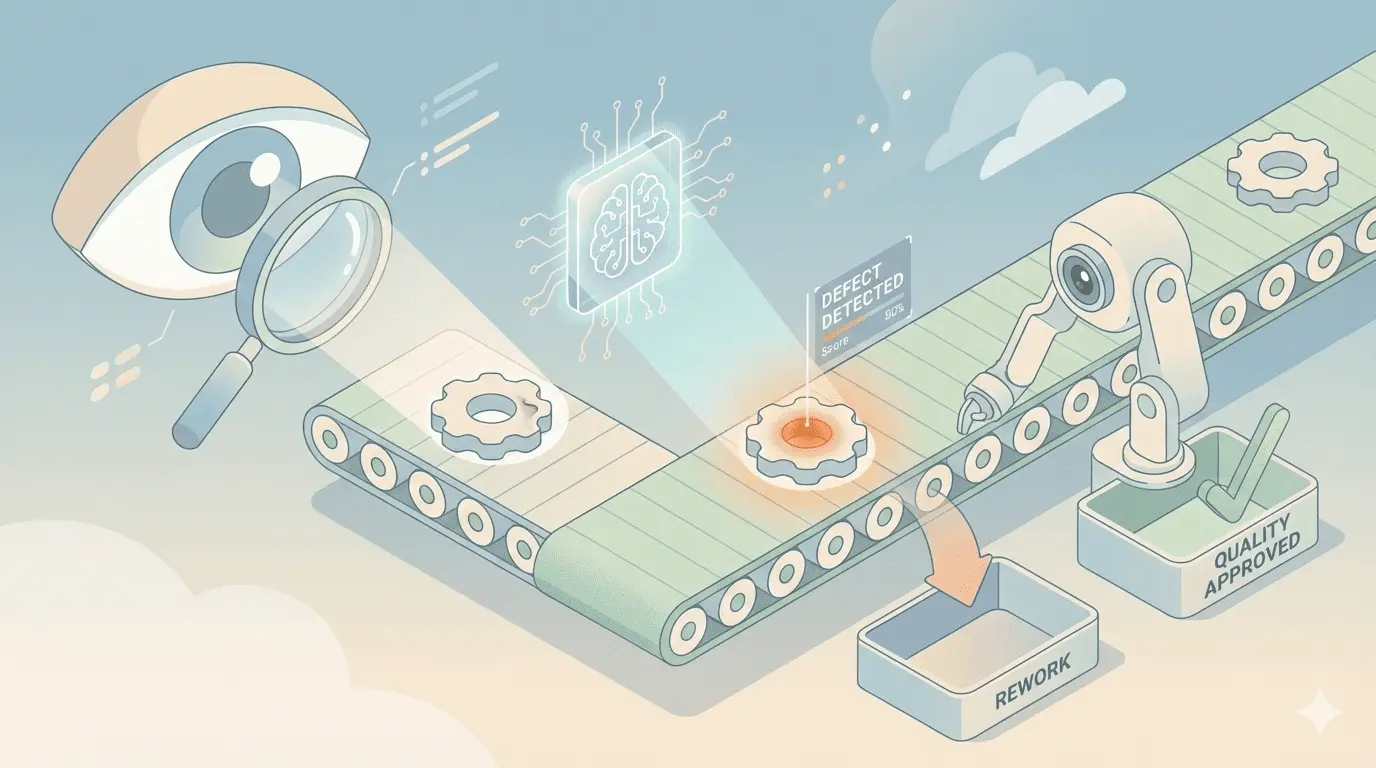

The New Inspector: AI-Powered Computer Vision

AI-driven quality control systems solve for these constraints by offering a new kind of inspector—one that is tireless, hyper-consistent, and infinitely scalable. At the core of this transformation is a combination of high-resolution imaging (cameras, X-ray, thermal) and sophisticated machine learning models.

How the System Actually Works: A Four-Stage Framework

-

Data Acquisition & Problem Scoping

The journey begins not with algorithms, but with collaboration. Engineers and data scientists work alongside quality experts to define the specific defects: scratches, discolorations, dimensional deviations, assembly errors, etc. High-quality image data is then collected—thousands of images of both "good" parts and parts with various documented defects. This foundational dataset is critical; it's the textbook from which the AI will learn. -

Model Training & Validation

Using this labeled dataset, a machine learning model—typically a deep convolutional neural network (CNN)—is trained. It learns to identify the complex visual patterns and subtle pixel-level variations that correspond to each defect type. The model is then rigorously validated on a separate set of images it has never seen, measuring its precision and recall to ensure it meets real-world accuracy requirements (often exceeding 99.5% in controlled conditions). -

Deployment & Integration

The trained model is deployed to "edge" devices or servers connected directly to the production line. Cameras are positioned at critical inspection points, and the system is integrated with the line's controls. In milliseconds, the AI analyzes each product's image, makes a pass/fail determination, and can automatically trigger a reject mechanism or alert an operator. -

Continuous Learning & Adaptation

Unlike a static rules-based system, a well-architected AI solution continues to learn. When a borderline case is flagged and reviewed by a human, that feedback is fed back into the system. It can also be retrained to recognize new defect types that emerge from material changes or process shifts, ensuring the system evolves with the production line.

Beyond Visual Inspection: Multi-Modal AI Quality

The most advanced implementations are moving beyond simple visual inspection:

* Auditory AI: Analyzing sounds from machinery (e.g., presses, motors) to detect anomalies predictive of future failures or defective products.

* Tactile & Force-Feedback AI: Using data from sensors to ensure assembly operations meet precise torque or pressure specifications.

* Generative AI for Root Cause Analysis: When a defect pattern is detected, AI can cross-reference it with thousands of data points from other machines (temperature, humidity, vibration, operator logs) to suggest the most probable root cause, dramatically speeding up corrective actions.

Quantifying the Transformation: Real-World Impact

The theoretical advantages of AI are compelling, but the field data is even more so. Manufacturers across sectors—from semiconductors and automotive to pharmaceuticals and consumer packaged goods—report transformative results:

- Dramatic Reduction in Defect Escapes: Companies routinely achieve 90-95% reductions in defects reaching customers, directly protecting brand reputation and eliminating recall costs.

- Optimized Material Usage: By catching defects earlier in the process, scrap and rework rates can fall by 25-40%, contributing directly to sustainability goals and cost savings.

- Unlocked Production Throughput: Inspection speeds can increase by 200% or more, removing a key bottleneck and allowing production lines to run at their designed capacity without quality trade-offs.

- Accelerated ROI: While implementation requires investment, the combination of higher quality, less waste, and increased throughput typically delivers a full return on investment (ROI) within 12 to 18 months.

- Upskilling the Workforce: Rather than replacing jobs, AI often shifts the role of quality personnel from monotonous visual screening to more valuable tasks like system oversight, exception handling, and process engineering.

Navigating the Implementation Journey

Adopting AI for quality control is a strategic initiative, not just a technology purchase. A successful rollout follows a deliberate path:

- Start with a Focused Pilot: Identify a single, high-impact production line or a specific, costly defect type. Choose a process with clear metrics, good data availability, and strong operational support. A successful pilot builds internal credibility and provides a learning blueprint.

- Build the Cross-Functional Team: Success requires a coalition: quality engineers, production floor managers, IT/OT specialists, and data scientists. Their combined expertise is essential for scoping, integration, and adoption.

- Prioritize Data Infrastructure: Ensure you can reliably capture, store, and manage the high-volume image data required for training and operation. This often involves upgrading network and compute resources at the edge of the factory floor.

- Choose the Right Partner/Platform: Most manufacturers partner with specialized AI software providers. Evaluate them based on their industry experience, platform ease-of-use (for your engineers), and the robustness of their continuous learning capabilities.

- Plan for Scale from Day One: Design your pilot with scalability in mind. How will the solution integrate with your Manufacturing Execution System (MES)? How will models be managed across multiple lines or global factories? Early architectural planning prevents costly rework later.

The Future of Quality: Autonomous and Predictive

The evolution is already underway. The next frontier moves from detection to prevention.

* Predictive Quality: AI models will analyze data from earlier in the production process (e.g., raw material properties, machine performance metrics) to predict the likelihood of a defect occurring before it happens, enabling pre-emptive adjustments.

* Self-Optimizing Production: Closed-loop systems will use AI inspection results to automatically fine-tune manufacturing parameters in real-time, creating a self-correcting production environment.

* Democratized AI Tools: No-code/low-code AI platforms will empower quality engineers—not just data scientists—to build and deploy new inspection models, dramatically speeding up innovation.

Conclusion: Quality as a Strategic Advantage

The integration of AI into quality control is no longer a speculative "future of manufacturing" topic—it is a present-day imperative for competitiveness. It transforms quality from a necessary cost center and bottleneck into a strategic, data-driven engine for efficiency, cost savings, and customer trust.

The question for manufacturing leaders is no longer if AI will play a role in their quality systems, but how soon and how comprehensively they can deploy it. The manufacturers who embrace this shift today are not just improving their inspection lines; they are building the resilient, efficient, and intelligent operations that will define industry leadership for the next decade. The era of AI-powered quality is here, and it sees everything.